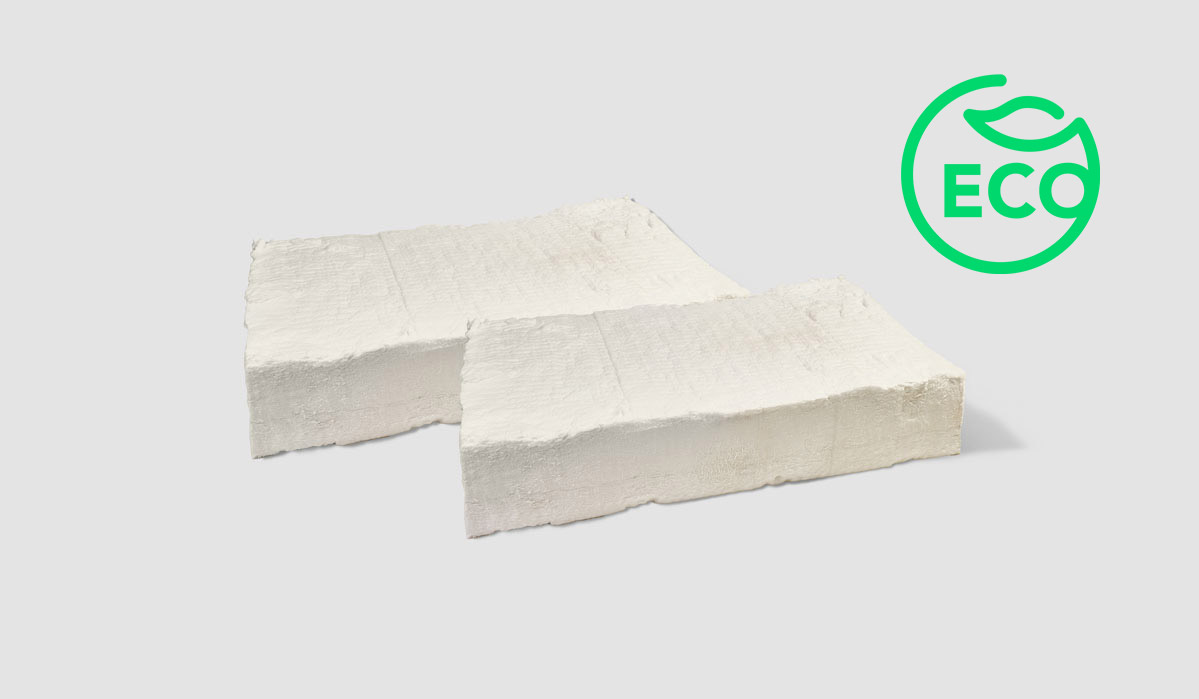

Type

Monolithic fiber logs made from high-temperature, low-biopersistence (LBP) fiber.

Benefits

- Proven technical solution

- Low shot technology

- Excellent insulation performance

- High handling strength

- Unaffected by most chemicals

- Excellent thermal stability

- Thermal shock resistant

- Exempt from carcinogenic classification

Temperature Range

The SoliSlab™ ULS logs have a classification temperature of 1200°C.

The maximum continuous use temperature provided on the datasheet is indicative and only applies in a clean, oxidizing atmosphere.

Typical applications

- Furnace car linings in ceramics and glass

- Precursor material for manufacturing monolithic fiber modules

- In-situ shapes for viewports and corners in fiber linings

- General technical insulation for furnaces and technical installations